WIRE EDM SERVICES

Precision Wire EDM Machining for Complex & Tight-Tolerance Parts

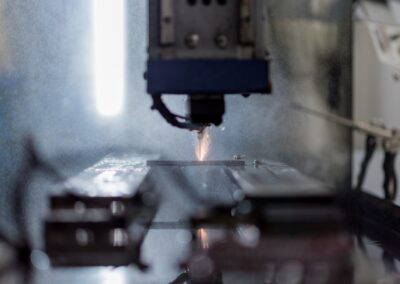

Nytron offers high-accuracy Wire EDM machining for components that require fine detail, tight tolerances, and complex geometries. Using advanced Sodick Wire EDM systems, we deliver precision cutting with exceptional repeatability and the ability to process hardened or exotic materials without distortion.

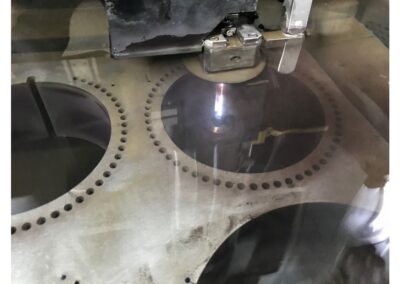

Wire EDM is ideal for manufacturing parts that demand sharp internal corners, thin walls, intricate contours, and extremely accurate profiles that conventional machining cannot achieve.

High-Accuracy Wire EDM for Complex Geometries

Nytron delivers high-precision Wire EDM machining for components that require exceptional accuracy, intricate geometries, and repeatable quality. Our advanced Sodick Wire EDM systems allow us to cut hardened materials, complex contours, micro-features, and tight-tolerance profiles with consistent dimensional stability.

Whether you’re producing fine-detail prototypes, custom tooling components, or high-accuracy production parts, Wire EDM provides clean, burr-free cutting with no mechanical distortion. We support a wide range of conductive materials, from tool steels and stainless steels to titanium, nickel alloys, copper alloys, carbide, and more.

Performance Indicators

%

Precision & Accuracy

%

Material Compatibility

%

Working Dimensions

%

Material Waste

%

Burr Formation

%

Part Distortion

Why EDM Delivers Exceptional Precision With Minimal Waste

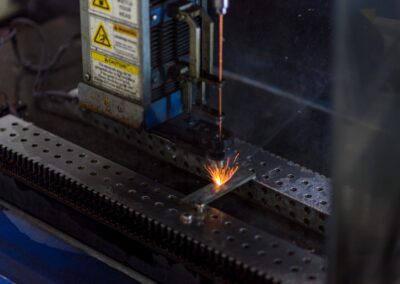

EDM cutting is known for its ability to create extremely thin kerf widths, often much narrower than traditional machining methods. Because the process uses a charged wire instead of a physical cutting tool, the material removal is precise and controlled, resulting in significantly lower material waste, a major advantage when working with expensive alloys or hardened steels.

The non-contact nature of the process also prevents tool pressure, allowing thin-wall features, fine detail work, and tight-tolerance cuts to maintain perfect stability throughout machining. This combination of accuracy, efficiency, and clean edge quality makes EDM one of the most effective technologies for producing detailed geometries, sharp internal corners, and repeatable precision across prototype and production work.

Our Wire EDM Capabilities

The primary technical capabilities of our Wire EDM equipment, covering part size, accuracy, wire options, and compatible materials.

Work Envelope & Part Capacity

Our Wire EDM systems support workpieces up to approximately 24″ in X travel, 16″ in Y travel, and 14″ in Z travel, with part weights up to around 1,700 lbs depending on fixturing. This allows us to cut both small, intricate components and larger blocks or plates while maintaining stable dimensional accuracy.

Precision Tolerances & Accuracy

We regularly achieve tolerances in the range of ±0.0001″ to ±0.0002″ using multi-pass roughing and skim finishing strategies. This ensures precise form accuracy, reliable straightness across deep cuts, and repeatable performance for components requiring tight dimensional control.

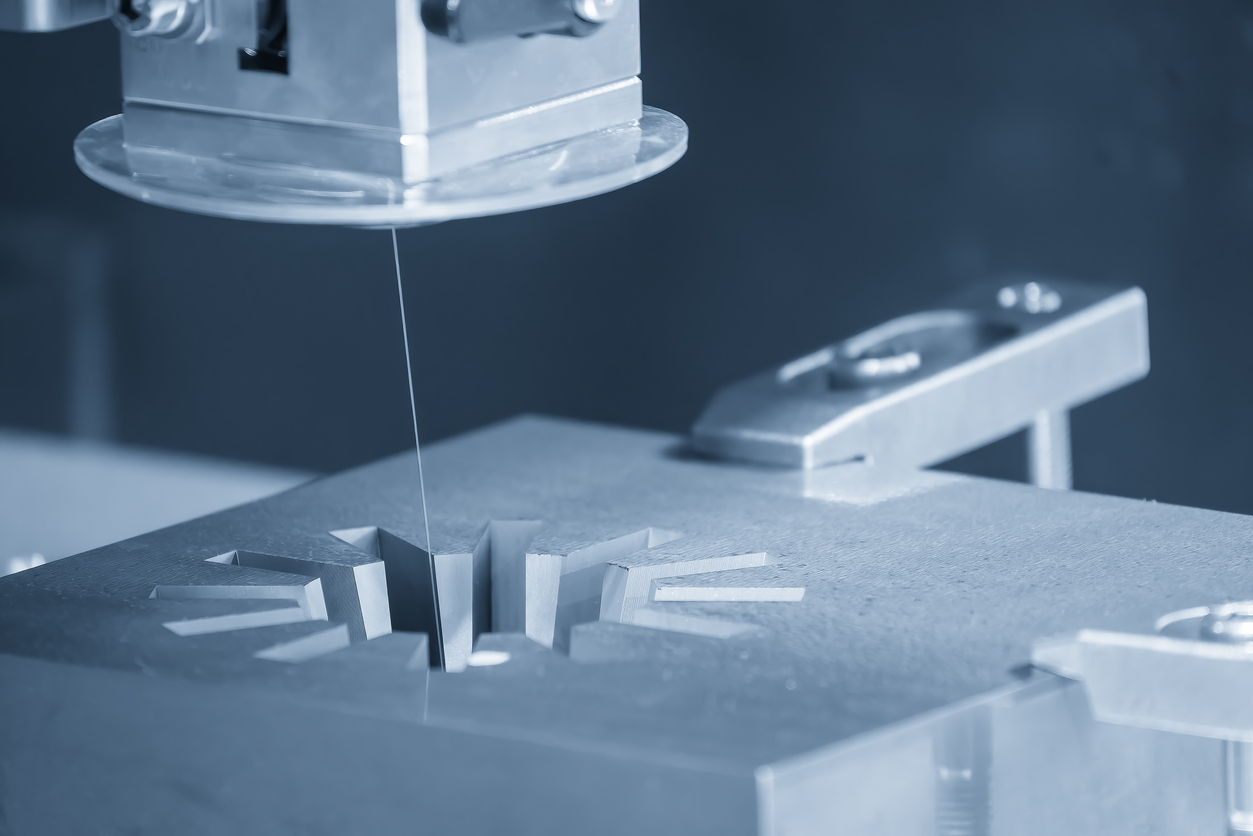

Wire Size & Surface Finish Capability

Available wire diameters range from fine 0.004″ wire for micro-features up to 0.012″ for thicker materials or faster roughing. Finishing passes can produce surfaces as fine as 4–8 Ra, with controlled spark-gap settings that minimize recast and maintain clean, burr-free edges.

Material Compatibility & Hardness Range

Wire EDM allows accurate cutting of any conductive material, including hardened tool steels up to 70+ HRC, stainless alloys, titanium, nickel-based alloys, carbide, copper, and brass. Because the process is non-contact, these materials can be machined in their fully heat-treated condition without distortion.

SODICK TECHNOLOGY

Sodick is widely recognized as a leader in EDM machining technology, offering exceptional accuracy, stable motion control, and consistently clean cutting results. Their wire EDM systems use advanced linear motor technology and precise spark management, allowing for detailed geometries, tight-tolerance features, and smooth surface finishes across a wide range of conductive materials.

Because Sodick machines excel at maintaining accuracy on hardened steels, stainless alloys, titanium, carbide, and other difficult materials, they are trusted throughout the precision manufacturing industry. By using Sodick Wire EDM equipment, we ensure every part benefits from reliable repeatability, consistent edge quality, and the high precision needed for both prototype and production work.

Quality You Can Trust

Our Wire EDM process is built on a commitment to precision, consistency, and reliable results on every part we produce. By combining advanced Sodick technology with controlled machining environments and careful process monitoring, we maintain tight tolerances, clean edge quality, and repeatable accuracy across all project sizes. Every job is handled with the same level of detail, from one-off prototypes to full production runs, ensuring you receive parts that meet your specifications with dependable, measurable quality. When you choose our EDM services, you’re choosing a process designed for accuracy, stability, and long-term performance you can trust.

TURNKEY PROJECTS

Production Machining

Production runs from 200pcs to 100,000pcs

TURNKEY PROJECTS

Rapid Prototype Machining

Advanced Rapid Prototyping Technology