AS9100 Rev D & ISO9001:2015

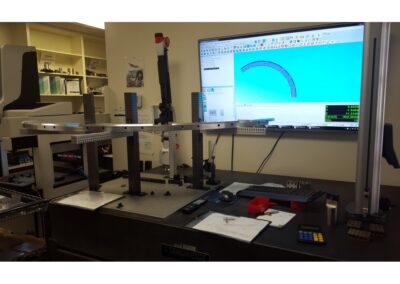

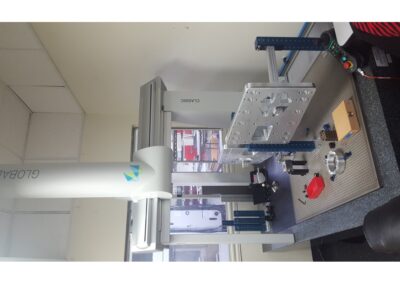

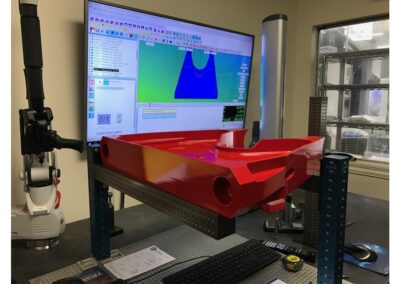

Temperature Control Precision Inspection

Nytron Aerospace is committed to supplying quality products & services that not only meet, but exceed customer requirements.

Quality Principles:.png) Nytron Aerospace defines it as 100 percent conformance to requirements, internal and external. The net effect is total customer satisfaction.

Nytron Aerospace defines it as 100 percent conformance to requirements, internal and external. The net effect is total customer satisfaction..png) It requires continuous improvement in all areas with a goal of error-free work (zero defects)

It requires continuous improvement in all areas with a goal of error-free work (zero defects).png) It is achieved by a system of prevention, supported through effective monitoring and tracking of key measurable and customer feedback as well as self-auditing of systems, processes and procedures.

It is achieved by a system of prevention, supported through effective monitoring and tracking of key measurable and customer feedback as well as self-auditing of systems, processes and procedures.

Nytron Aerospace relies upon the strength of its employees to achieve these requirements, encouraging employee involvement and teamwork in a positive work environment. Through this Policy, Nytron Aerospace will maintain and build upon its competitive advantage in the worldwide aerospace market.

AS9100 Rev D & ISO9001:2015

Temperature Control Precision Inspection

Quality Principles:

.png) Nytron Aerospace defines it as 100 percent conformance to requirements, internal and external. The net effect is total customer satisfaction.

Nytron Aerospace defines it as 100 percent conformance to requirements, internal and external. The net effect is total customer satisfaction..png) It requires continuous improvement in all areas with a goal of error-free work (zero defects)

It requires continuous improvement in all areas with a goal of error-free work (zero defects).png) It is achieved by a system of prevention, supported through effective monitoring and tracking of key measurable and customer feedback as well as self-auditing of systems, processes and procedures.

It is achieved by a system of prevention, supported through effective monitoring and tracking of key measurable and customer feedback as well as self-auditing of systems, processes and procedures.

Nytron Aerospace relies upon the strength of its employees to achieve these requirements, encouraging employee involvement and teamwork in a positive work environment. Through this Policy, Nytron Aerospace will maintain and build upon its competitive advantage in the worldwide aerospace market.

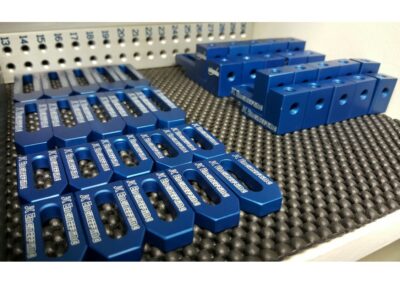

Inspection Gage Tracking

Nytron Aerospace‘s Inspection Gage Management eliminates many issues related to tool control, leading to increased productivity and lower risk. The system incorporates hardware, software, and RFID technology to help us efficiently manage our calibration & tool use. Proper organization is essential in order to keep track of the vast quantity of inspection tools available Nytron Aerospace’s Inspection Department.

While tools are on the floor, Nytron Aerospace ERP track their movements across the facility. This limits the time spent searching for lost gages, eliminates damage, and helps to maintain AS9100 compliance—all of which contribute to increased production and reduced costs.

TURNKEY PROJECTS

Production Machining

Production runs from 200pcs to 100,000pcs

TURNKEY PROJECTS

Rapid Prototype Machining

Advanced Rapid Prototyping Technology