LET NYTRON AEROSPACE RUN YOUR NEXT PROTOTYPE BEFORE WE RUN THE PRODUCTION!

✔ Nytron Aerospace leverages best practices, advanced rapid prototyping technology, and a commitment to total quality to ensure our customers have the utmost confidence in our capabilities to deliver value on-time – every time.

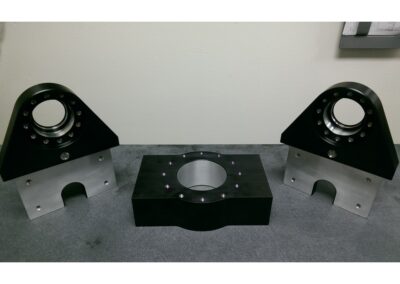

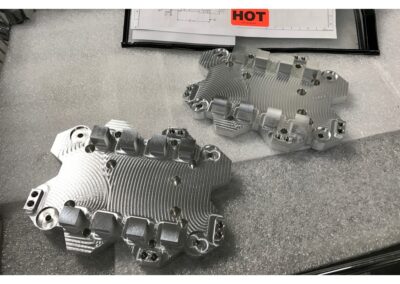

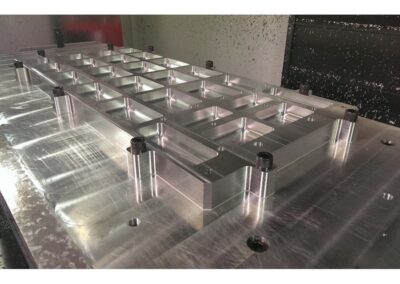

✔ We offer both prototyping, tooling and large volume production capability using a variety of materials. Parts are delivered complete, including such additional services as assembly, plating, painting, powder coat, and screen printing. Average lead-time is 2-3 weeks. Nytron Aerospace fabricates each part using a documented process flow with a 100% final inspection.

✔ Nytron Aerospace’s engineers, programmers, machinists, and staff work seamlessly with customers to enhance the understanding of their needs and expectations. Our solutions are optimized to help companies maximize their profit potential. We strive to provide our customers with affordable exceptional service and products on a consistent basis.

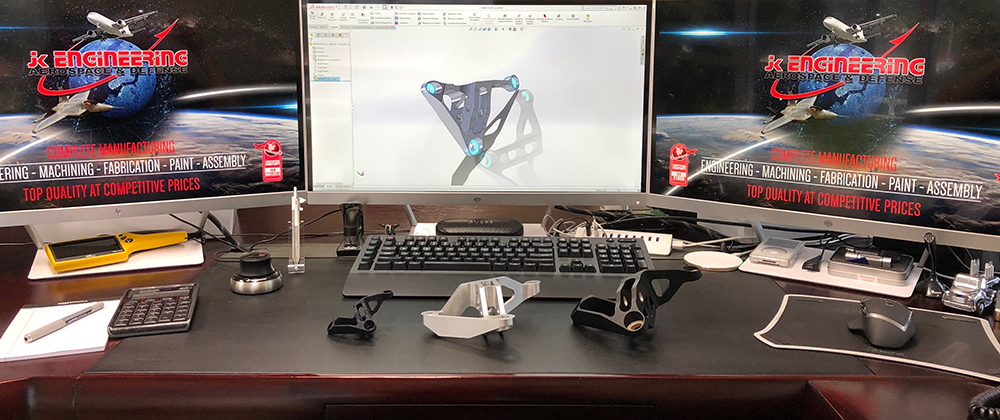

3D Printing Utilized

Nytron Aerospace utilizes 3D printing of prototype parts to help us better visualize the part from the very beginning. Having a 3D printed part is an advantage over conventional/traditional models for developing layouts and planning techniques in lean activity.