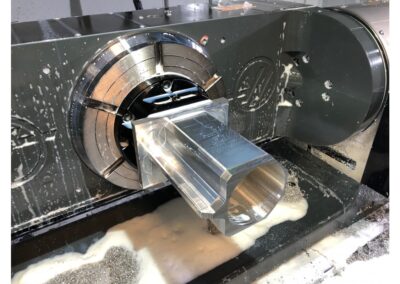

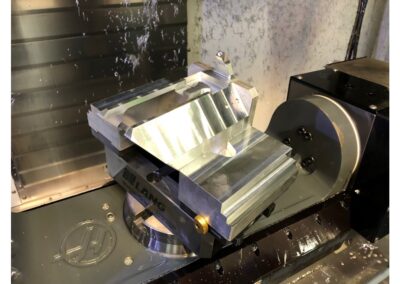

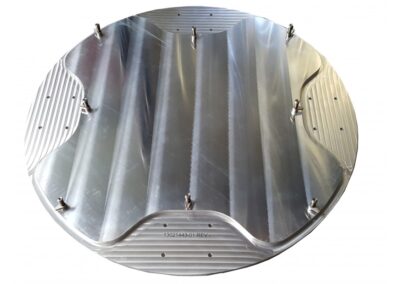

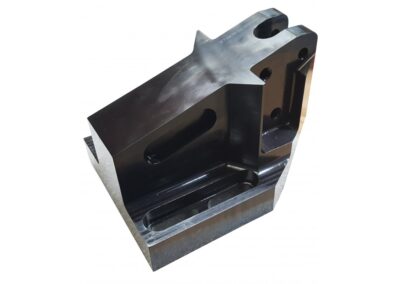

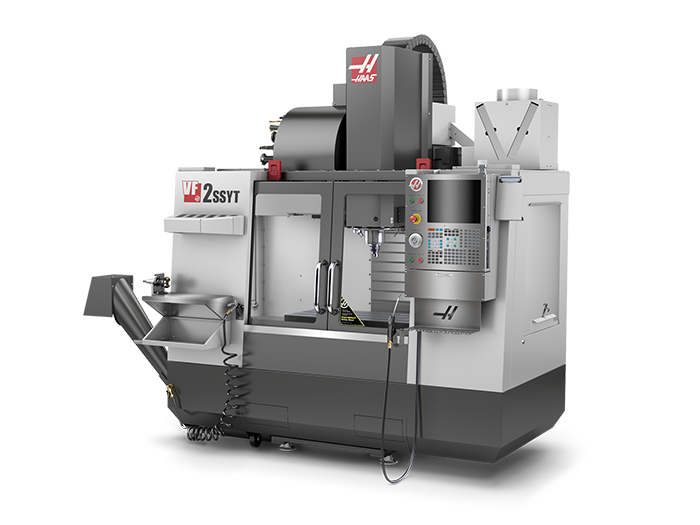

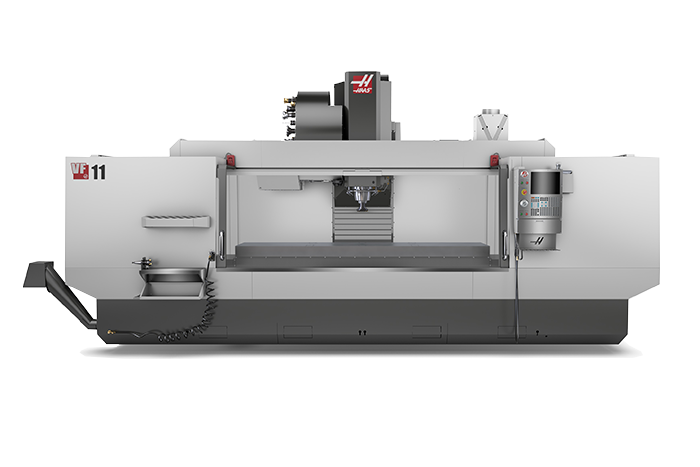

Nytron Aerospace employs a wide range of milling machines to complete most any CNC Milling project. All of our CNC Milling machines have a 4th axis rotary & trunnion for complex machining. The most advanced machining techniques are utilized to achieve the best results every time. Our milling machines are high end late model HAAS made VMC’s, which are the most versatile CNC Machines available on the market today to allow us the flexibility to maintain repeatability while still being able to manufacture parts quickly. Most of our CNC mills are super speed models that are capable of extremely high speeds – up to 12,000 rpm – which is needed for machining with very small parts. We also have high speed 50,000RPM attachments for machining tiny features using very small diameter tools to create enough surface speed for cutting.

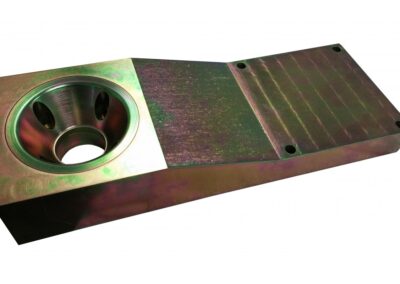

We are also experts in building fixtures to hold the parts in place while machining. Some of these quick fixtures consist of a vacuum plate and quick change plates, as well as custom fixturing per job requirements. This is a critical skill needed to be efficient and accurate when producing thousands of parts that need to keep very close tolerances. Fixtures also play a huge role in multi operation machining where the part needs to be machined in separate stages to reach different sides of the part to make a complex piece.

Equipment Highlights:

.png) 3-Axis & 5-Axis Milling Up to 120″X, 40″Y, 40″Z

3-Axis & 5-Axis Milling Up to 120″X, 40″Y, 40″Z

.png) 4-Axis Milling Up to 16″ Dia x 40″ X Travel

4-Axis Milling Up to 16″ Dia x 40″ X Travel

.png) Advanced Lean Manufacturing Processes

Advanced Lean Manufacturing Processes

.png) Dedicated Setups Reduced Lead-Time

Dedicated Setups Reduced Lead-Time

.png) Through The Tool Coolant

Through The Tool Coolant

.png) Super Speed Machining

Super Speed Machining

.png) In Machine Probing

In Machine Probing

.png) Rigid Tapping

Rigid Tapping

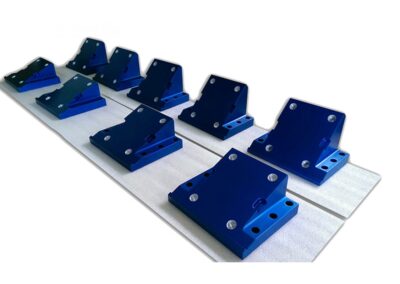

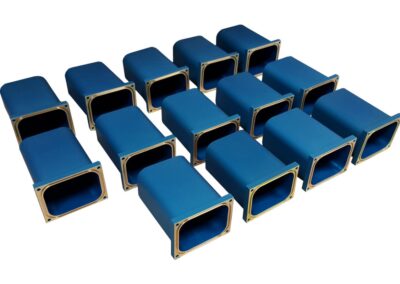

Turnkey Projects

Production Machining

Production runs from 200pcs to 100,000pcs

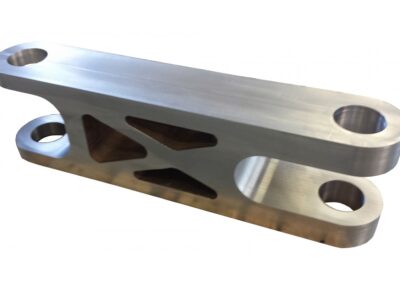

Turnkey Projects

Rapid Prototype Machining

Advanced Rapid Prototyping Technology