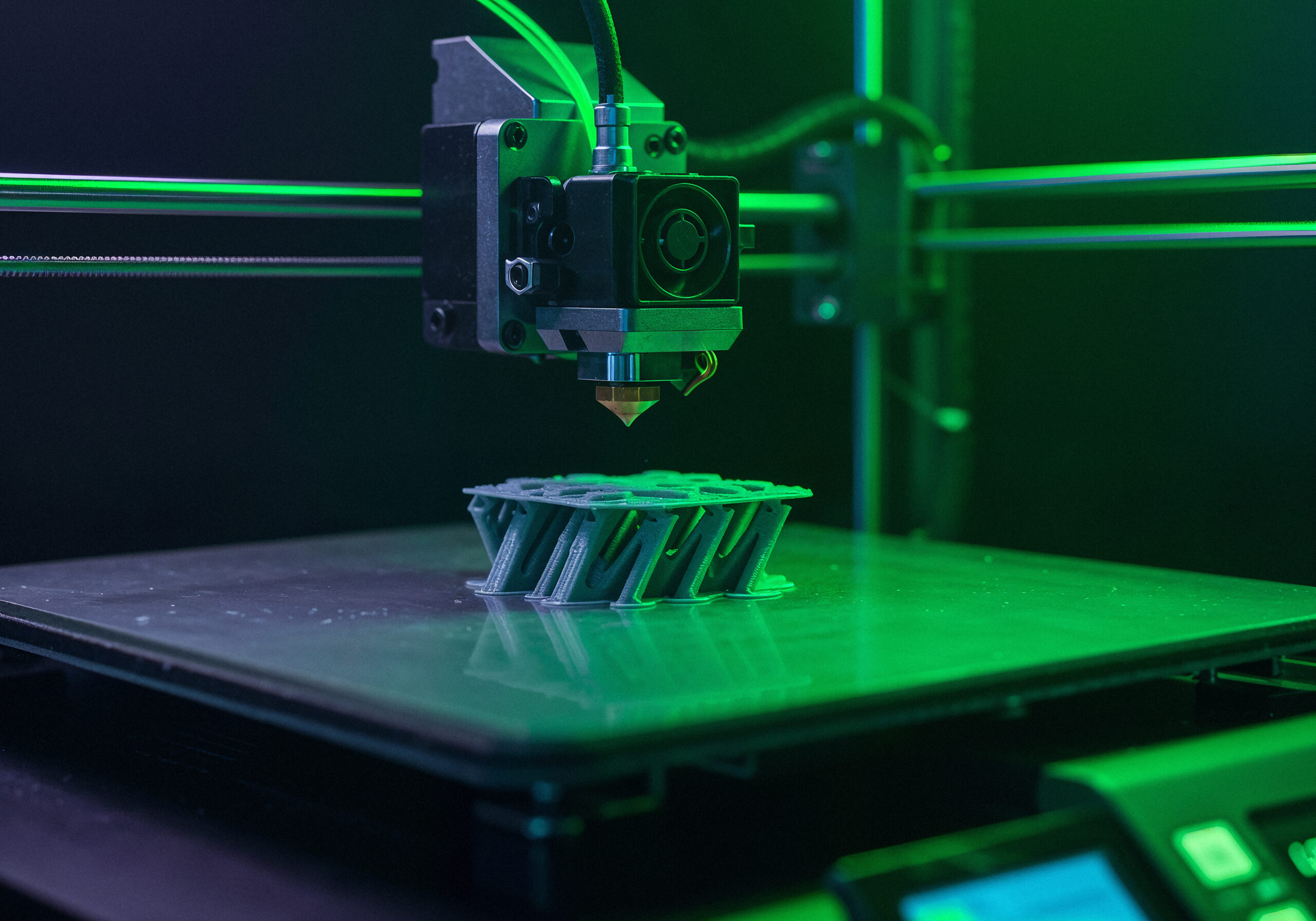

3D Printing & Additive Manufacturing Services

From prototype to production — precision parts made layer by layer.

Nytron provides high-quality 3D printing services using advanced FDM and resin-based technologies. We produce accurate, durable, and functional parts for industries including aerospace, automotive, electronics, and medical.

Rapid. Accurate. Production-Ready.

3D printing transforms digital designs into physical components with exceptional precision and speed.

At Nytron, we use industrial-grade additive manufacturing systems capable of producing both prototype and end-use parts, optimized for strength, surface quality, and dimensional accuracy.

Our team supports every stage, from CAD model validation and print optimization to finishing, assembly, and inspection. Whether you need a one-off prototype or small-batch production, our process ensures repeatable quality and tight tolerances across all prints.

Our 3D Printing Capabilities

Nytron’s FDM printing workflow is designed to cover every stage of additive manufacturing, from design validation to post-processing. Our equipment, materials, and experience ensure production-quality results every time.

Industrial-Grade FDM Printing

Large-format printers capable of high-strength, dimensionally stable parts with layer resolutions down to 0.05 mm. Ideal for engineering prototypes, tooling, and functional end-use parts.

Multi-Material & Dual-Extrusion Printing

Dual extruder allow printing with two materials or colors simultaneously, enabling soluble support structures, flexible sections, or multicolor branding .

Engineering Thermoplastics

We print with a broad selection of high-performance materials, including PLA, PET-G, ABS, ASA, Nylon, and Carbon Fiber composites, each chosen for therequirements of your project.

Rapid Prototyping & Design Iteration

Bring concepts to life quickly. We optimize your CAD files for orientation, support, and infill to achieve strong, accurate prototypes ready for functional testing or client presentation.

Materials We Print

FDM technology allows us to print with a wide range of thermoplastics, each chosen for its mechanical strength, thermal stability, or flexibility. We fine-tune extrusion parameters for every material to ensure optimal adhesion, finish, and performance.

PLA & PET-G

Versatile and dimensionally stable materials ideal for visual models, prototypes, and lightweight production parts.

Common variants:

-

Standard and matte PLA

-

PET-G for strong, impact-resistant parts

-

Recycled and eco-based blends

ABS & ASA

High-strength polymers used in industrial and automotive environments where heat and UV resistance are required.

Common variants:

-

ABS+, ASA (UV-stable)

-

High-temperature and chemical-resistant grades

-

Machinable, paintable prototypes

Nylon (PA) & Carbon Fiber Composites

High-performance materials offering excellent toughness and dimensional stability for demanding mechanical applications.

Common variants:

-

Nylon 6, Nylon 12

-

Carbon Fiber–reinforced Nylon

-

Kevlar and glass-filled blends

TPU & Flexible Filaments

Elastomeric materials for parts requiring flexibility, impact resistance, or soft-touch surfaces.

Common variants:

-

TPU 95A and 90A

-

TPE blends for seals and gaskets

-

Shock-absorbing mounts and vibration dampers

Specialty & Custom Filaments

Unique filaments engineered for performance or appearance.

Common variants:

-

Conductive and ESD-safe blends

-

Wood- and metal-filled PLA

-

Glow-in-the-dark, transparent, and color-changing filaments

Why Choose Nytron for FDM Printing

By specializing in FDM, Nytron delivers the most reliable and cost-effective additive manufacturing experience possible. Our focus ensures consistent quality, predictable performance, and faster turnaround times compared to hybrid or outsourced print services.

Highlights:

-

Dedicated FDM expertise and optimized print settings

-

Tight tolerances and consistent layer bonding

-

Affordable small-batch and prototype production

-

Wide material compatibility for mechanical and aesthetic needs

-

In-house finishing, assembly, and inspection

-

Scalable from single prints to ongoing production runs

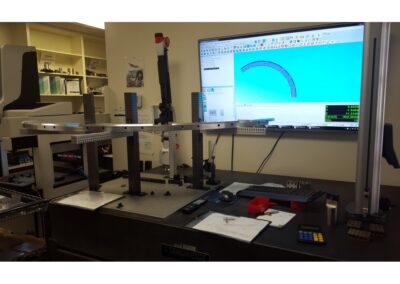

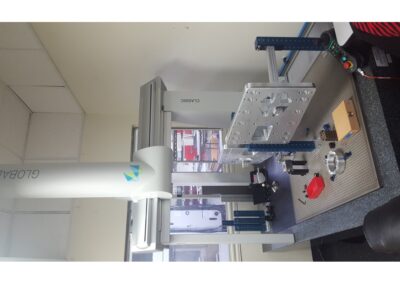

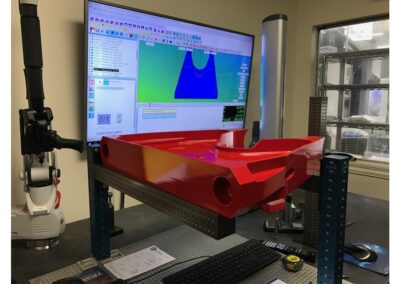

Precision You Can Measure

Every FDM print undergoes dimensional and visual inspection to verify accuracy and consistency. We track build settings and environmental parameters to maintain predictable results from project to project.

Highlights:

• Dimensional verification vs CAD model

• Layer height and extrusion consistency control

• Visual and surface quality inspection

• Calibration logs and build reports available on request

TURNKEY PROJECTS

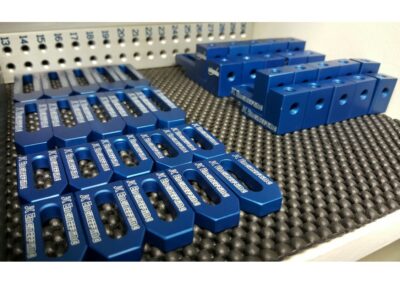

Production Machining

Production runs from 200pcs to 100,000pcs

TURNKEY PROJECTS

Rapid Prototype Machining

Advanced Rapid Prototyping Technology