HOLE POPPING EDM

High-Precision Small-Hole EDM Drilling

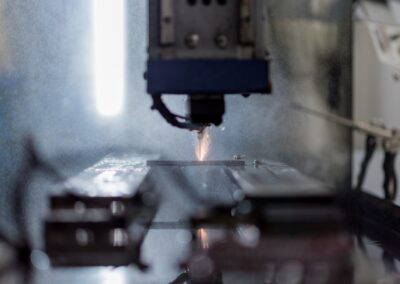

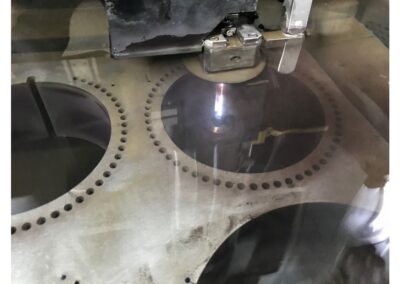

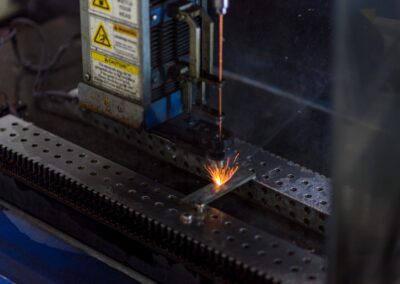

Hole-popping EDM (also known as small-hole EDM or EDM drilling) is a specialized machining process used to produce small-diameter, high-aspect-ratio holes in electrically conductive materials. Unlike conventional drilling, this process uses a tubular electrode and controlled electrical discharges to erode material, allowing holes to be created in hardened or heat-treated parts without tool breakage or distortion.

This process is commonly used for start holes for Wire EDM, deep straight holes, and precision features where traditional drilling methods struggle. Because the process is non-contact and uses continuous flushing through the electrode, hole-popping EDM delivers accurate results even at extreme depths and small diameters.

Why Hole-Popping EDM Is Essential for Precision Manufacturing

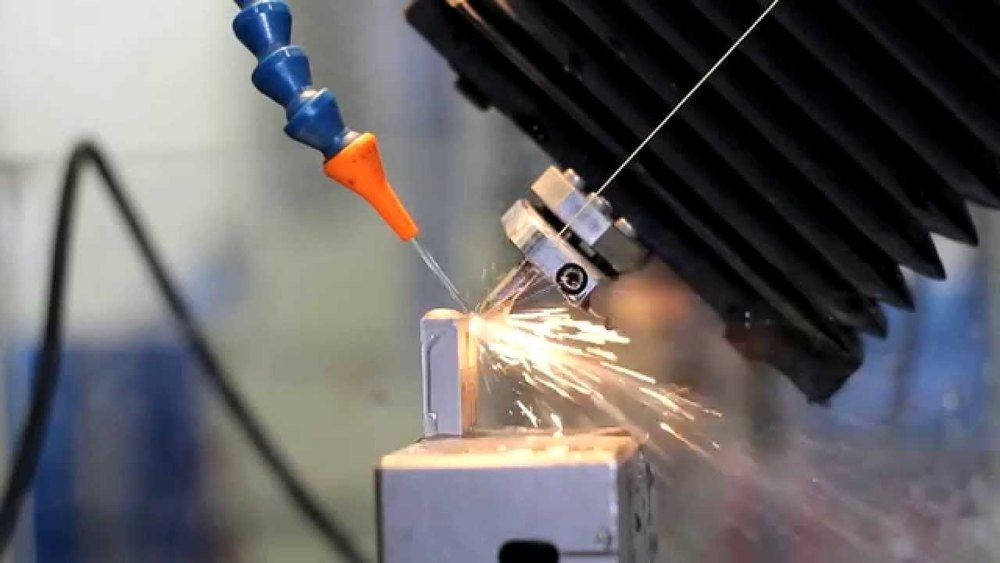

Small-hole EDM drilling is designed specifically for applications where very small, deep holes must be produced accurately and consistently. The process excels in hardened materials, exotic alloys, and situations where tool access, drill breakage, or material hardness makes conventional drilling unreliable. Using a rotating tubular electrode with internal flushing, debris is continuously removed from the cut, allowing holes to remain straight and stable as depth increases. This makes hole-popping EDM an ideal solution for deep start holes, cooling passages, ejector pin holes, and precision features that require clean entry, controlled diameter, and repeatable results.

Performance Indicators

%

Material Compatibility

%

Deep-Hole Capability

%

Hole Accuracy & Straightness

%

Material Waste

%

Electrode Wear

%

Thermal Distortion

Reliable Small-Hole EDM You Can Count On

Our hole-popping EDM process is focused on consistency, accuracy, and repeatability, even on challenging materials and deep features. Each job is approached with controlled machining parameters to ensure stable hole formation, clean internal walls, and predictable results from the first hole to the last. Whether drilling a single start hole or producing multiple deep precision holes, the process delivers dependable outcomes for both prototype and production work.

Our Hole Popping EDM Capabilities

The primary technical capabilities of our Hole Popping EDM equipment, covering part size, accuracy, wire options, and compatible materials.

Work Envelope & Part Capacity

Our small-hole EDM drilling equipment supports compact to medium-size components within an approximate working envelope of 12–16 inches in X, 10–14 inches in Y, and 12–18 inches in Z. Parts can be securely fixtured to allow accurate vertical drilling and multi-hole patterns with consistent alignment.

Precision Tolerances & Accuracy

Small-hole EDM drilling delivers controlled accuracy by using a tubular electrode and continuous internal flushing. Typical achievable hole diameter tolerance ranges from ±0.0005″ to ±0.0010″, depending on hole diameter, material, and depth. Positional accuracy is commonly held within ±0.001″.

Wire Size & Surface Finish Capability

Small-hole EDM drilling supports hole diameters ranging from approximately 0.010″ up to 0.125″ (0.25–3.2 mm), with depth-to-diameter ratios exceeding 20:1 and, in many cases, significantly higher depending on material and diameter.

Material Compatibility & Hardness Range

Hole-popping EDM works on any electrically conductive material, independent of hardness. Common materials include hardened tool steels (up to 70+ HRC), stainless steels, titanium, nickel alloys, carbide, copper, and brass. Parts can be drilled after heat treatment with no risk of mechanical distortion.

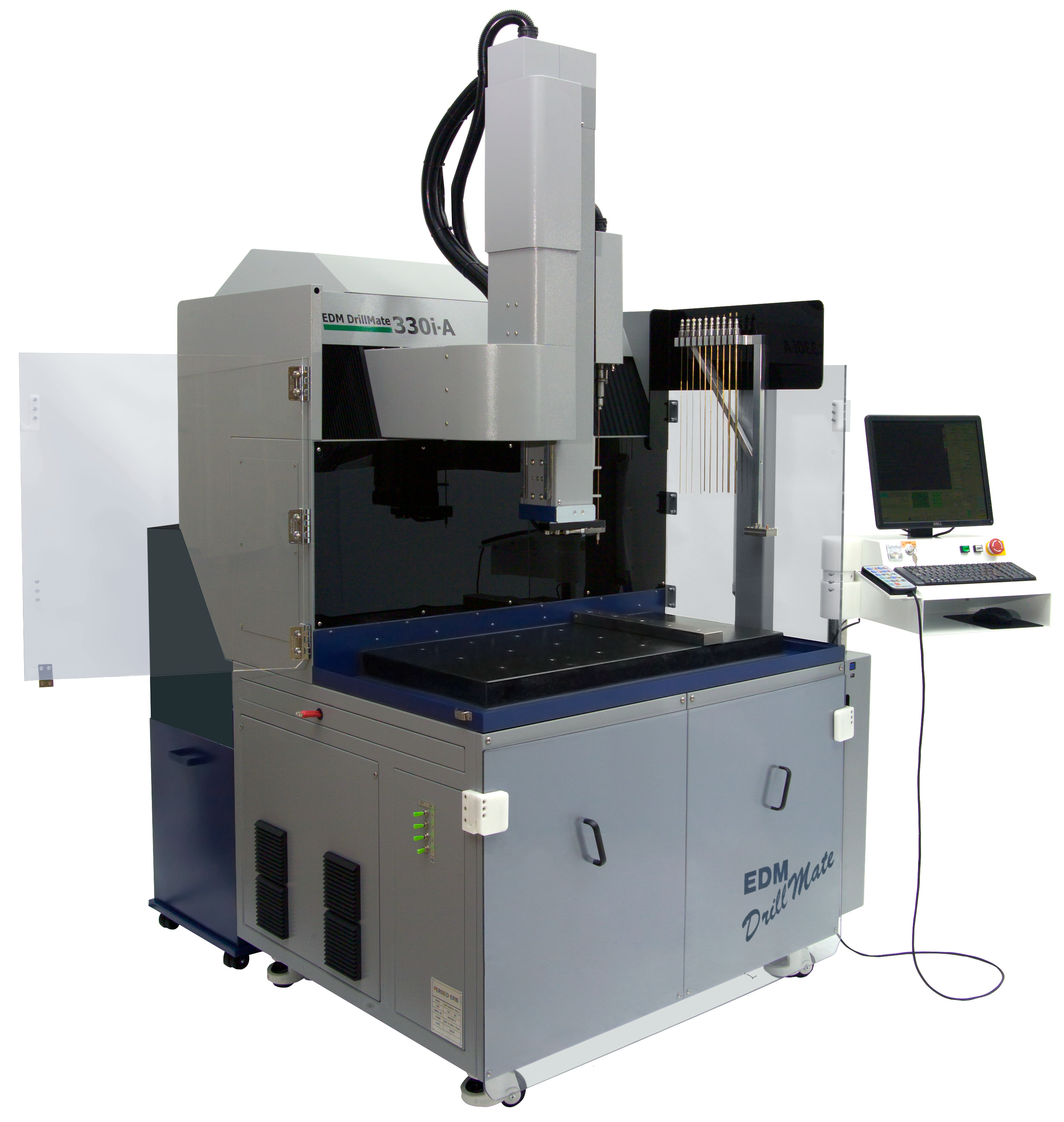

High-End EDM Technology

Our EDM operations are powered by premium, industrial-grade technology designed for precision, stability, and long-term reliability. The systems we use are built around advanced linear motion control, highly accurate servo systems, and carefully regulated spark energy, allowing consistent performance even during extended machining cycles. This level of control ensures tight dimensional accuracy, clean surface quality, and repeatable results across a wide range of materials and geometries.

By using high-end EDM platforms known throughout the industry for their engineering quality, we maintain stable cutting conditions, predictable material removal, and minimal thermal influence on the workpiece. This technology excels in fine-detail work, hardened materials, deep features, and complex internal geometries where precision and consistency are critical. The result is a machining process that delivers reliable accuracy, clean edges, and measurable quality from first piece to final production.

Quality You Can Trust

Our EDM process is built on a commitment to precision, consistency, and reliable results on every part we produce. By combining advanced Sodick technology with controlled machining environments and careful process monitoring, we maintain tight tolerances, clean edge quality, and repeatable accuracy across all project sizes. Every job is handled with the same level of detail, from one-off prototypes to full production runs, ensuring you receive parts that meet your specifications with dependable, measurable quality. When you choose our EDM services, you’re choosing a process designed for accuracy, stability, and long-term performance you can trust.

TURNKEY PROJECTS

Production Machining

Production runs from 200pcs to 100,000pcs

TURNKEY PROJECTS

Rapid Prototype Machining

Advanced Rapid Prototyping Technology