SINKER EDM SERVICES

Sinker EDM – Precision Cavity & Complex Geometry Machining

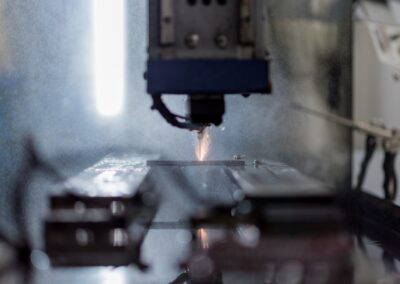

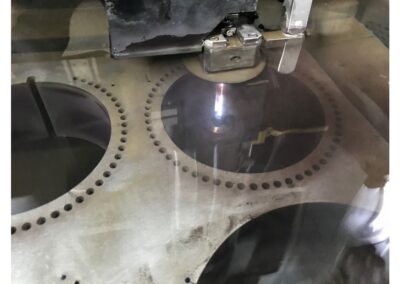

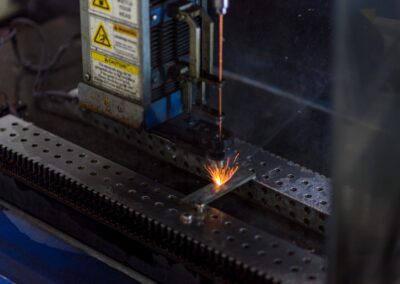

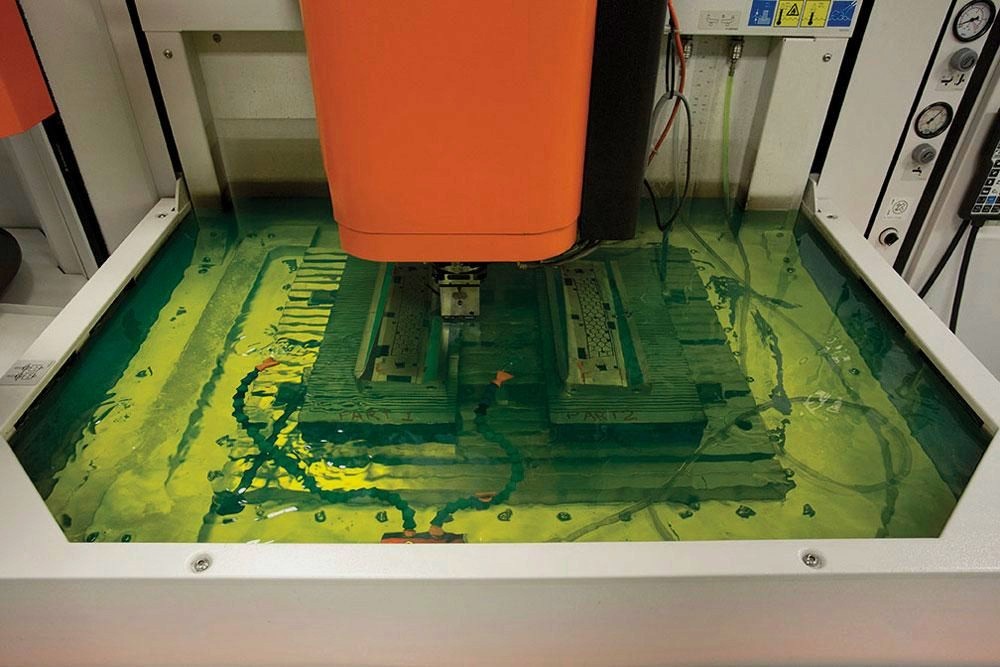

Our Sinker EDM service offers the ability to create complex internal cavities, blind slots, deep pockets, and intricate 3D geometries with high repeatability and minimal mechanical stress. Because the process uses a shaped electrode submerged in dielectric fluid, not a cutting tool, we can machine hard materials, deep slots, and complex shapes that are virtually impossible with conventional milling or turning.

Whether you need mold cavities, die inserts, tooling pockets, custom components, or deep internal features, our Sinker EDM cell is engineered to deliver consistent quality, sharp internal corners, and reliable surface integrity.

Why Sinker EDM Matters for Modern Manufacturing

Sinker EDM enables us to produce internal geometries, blind cavities, undercuts, deep ribs and complex 3D features with precision and consistency, independent of material hardness. It excels especially where traditional machining would struggle — for example, in hardened tool steels, stainless steels, exotic alloys, or carbide. The non-contact spark erosion process avoids mechanical stress or distortion, which means parts can be machined even after heat treatment. Additionally, the use of a shaped electrode means we can replicate complex negative forms (mold cavities, dies, inserts) exactly, resulting in parts with highly accurate internal dimensions, sharp corners, and clean finishes.

Performance Indicators

%

Dimensional Accuracy

%

Complex Geometry Capability

%

Material Hardness Handling

%

Electrode Wear

%

Material Waste

%

Cavity Depth Stability

Why Choose Our Sinker EDM Services

Choosing our Sinker EDM services means opting for reliable, high-precision cavity making and part production in any conductive material. Our equipment and process controls ensure consistent spark parameters, stable dielectric flow, and precise electrode control for superior part quality. We handle everything from electrode design, roughing and finishing passes, to final washing and inspection, giving you peace of mind and repeatable results. Whether your project involves a single prototype cavity or complex multi-cavity tooling, we provide expert support and craftsmanship.

Our Sinker EDM Capabilities

The primary technical capabilities of our Sinker EDM equipment, covering part size, accuracy, wire options, and compatible materials.

Work Envelope & Part Capacity

Our Sinker EDM systems support a generous machining envelope, with an approximate working range of 13.8–23.6 in, 9.8–15.7 in, and 9.8–14.5 in, and the ability to handle workpieces up to 1,760 lbs, we can accommodate substantial components.

Precision Tolerances & Accuracy

Sinker EDM provides highly controlled spark erosion that maintains dimensional integrity throughout deep or complex cavities. Typical tolerance capability ranges around ±0.0002″–±0.0005″ depending on cavity depth, electrode geometry, and finishing passes.

Wire Size & Surface Finish Capability

Using graphite or copper electrodes ranging from small precision forms to large cavity tools, our sinker EDM process can achieve fine surface finishes down to ~12–16 Ra, with even finer results possible through extended finishing cycles.

Material Compatibility & Hardness Range

Sinker EDM is fully capable of machining any electrically conductive material, regardless of hardness. This includes tool steels up to 70+ HRC, stainless steels, titanium, nickel alloys, carbide, copper, and brass.

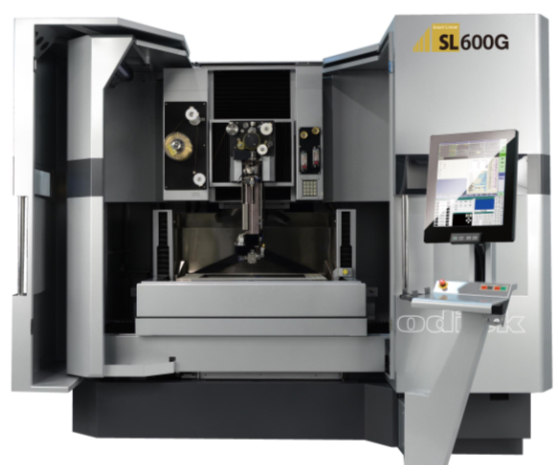

SODICK TECHNOLOGY

Sodick is widely recognized as a leader in EDM machining technology, offering exceptional accuracy, stable motion control, and consistently clean cutting results. Their wire EDM systems use advanced linear motor technology and precise spark management, allowing for detailed geometries, tight-tolerance features, and smooth surface finishes across a wide range of conductive materials.

Because Sodick machines excel at maintaining accuracy on hardened steels, stainless alloys, titanium, carbide, and other difficult materials, they are trusted throughout the precision manufacturing industry. By using Sodick Sinker EDM equipment, we ensure every part benefits from reliable repeatability, consistent edge quality, and the high precision needed for both prototype and production work.

Quality You Can Trust

Our Sinker EDM process is built on a commitment to precision, consistency, and reliable results on every part we produce. By combining advanced Sodick technology with controlled machining environments and careful process monitoring, we maintain tight tolerances, clean edge quality, and repeatable accuracy across all project sizes. Every job is handled with the same level of detail, from one-off prototypes to full production runs, ensuring you receive parts that meet your specifications with dependable, measurable quality. When you choose our EDM services, you’re choosing a process designed for accuracy, stability, and long-term performance you can trust.

TURNKEY PROJECTS

Production Machining

Production runs from 200pcs to 100,000pcs

TURNKEY PROJECTS

Rapid Prototype Machining

Advanced Rapid Prototyping Technology