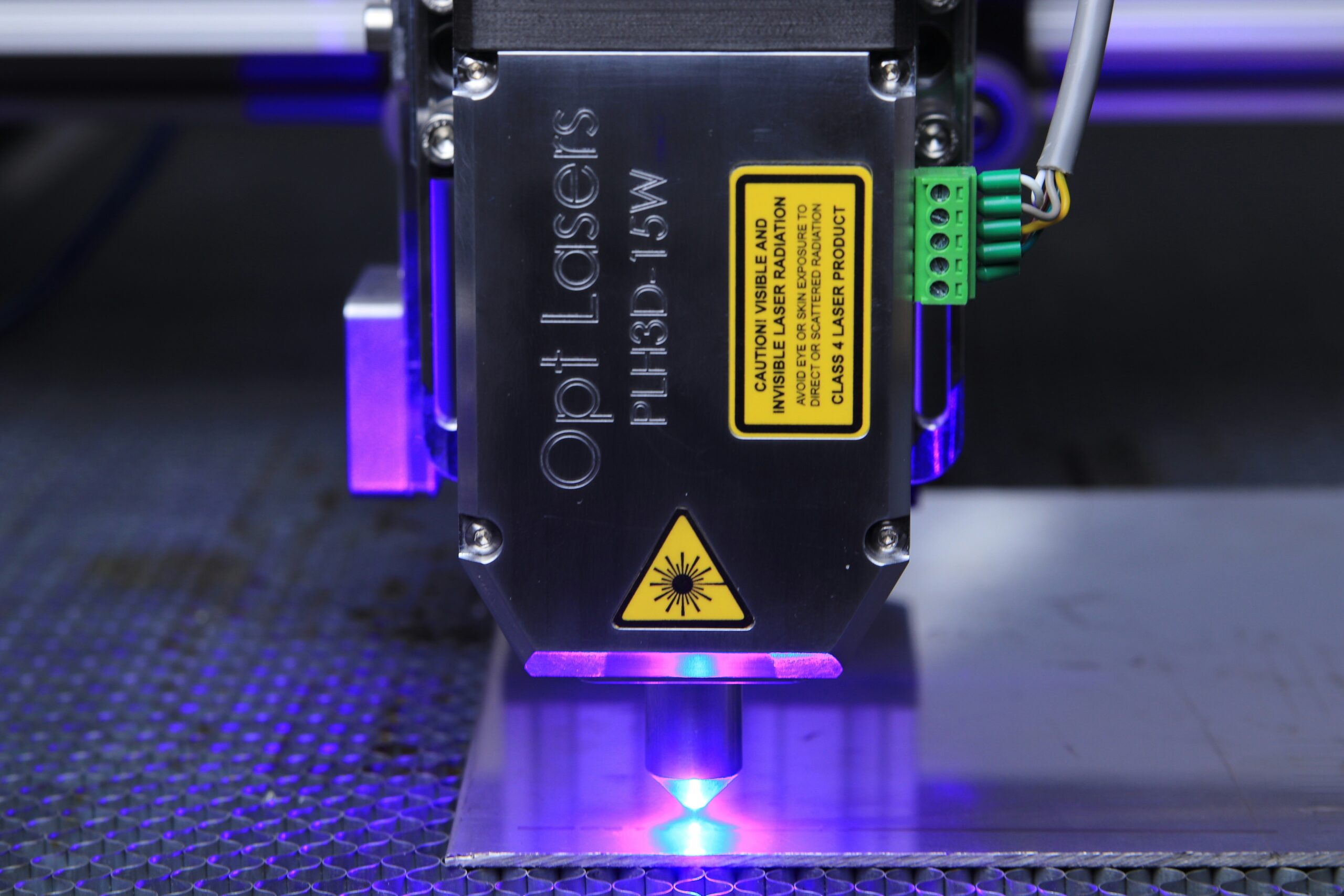

Laser Marking & Engraving Services

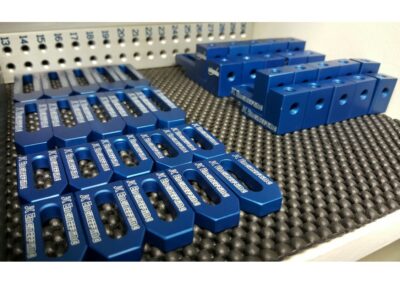

High-precision, permanent marking for metals, plastics, and engineered components.

Nytron delivers accurate, durable laser marking services for all industries, from aerospace and automotive to medical and industrial manufacturing. We specialize in creating clean, permanent, and fully traceable marks that meet even the most demanding quality standards.

Precision. Permanence. Traceability.

Laser marking is a fast, contact-free process that produces high-contrast, permanent identification on a wide range of materials.

At Nytron, we use industrial-grade laser systems capable of marking intricate designs, barcodes, serial numbers, logos, and alphanumeric text with exceptional accuracy and consistency.

Whether you need part traceability, branding, or compliance marking, our process ensures every mark is sharp, durable, and readable. By fine-tuning laser parameters for each material, we guarantee consistent results, achieving permanent identification without mechanical stress, surface damage, or consumables.

Our Laser Marking Capabilities

We offer a range of marking technologies and configurations to suit different materials and applications.

Laser Engraving

Deep material removal for lasting marks that resist abrasion, heat, and corrosion. Ideal for aerospace and industrial applications.

Laser Annealing

Oxidation-based color marking, perfect for stainless steel and medical-grade components where surface integrity must be preserved.

Laser Etching

Shallow engraving for high-speed marking of logos, serials, and text without compromising surface finish.

DataMatrix Marking

Machine-readable identification for parts requiring digital traceability.

Custom Logos

High-resolution logo and text marking to add professional branding directly to your parts.

Contrast Control

Adjustable laser parameters for matte, glossy, or dark markings on various substrates.

Versatile for Any Material

- Aluminum & Anodized Aluminum

- Stainless Steel & Titanium

- Brass & Copper

- Plastics & Composites

- Painted, Coated & Plated Surfaces

- Ceramics & Coated Materials

Lightweight and widely used across industries, aluminum allows for high-contrast, clean markings ideal for serials, logos, and traceability.

Examples include:

Raw or machined aluminum components

Anodized aluminum (clear, black, or colored)

Cast and extruded aluminum profiles

Aluminum nameplates and identification tags

Common in aerospace, defense, and medical applications, these materials require controlled marking to maintain corrosion resistance and integrity.

Examples include:

300 and 400 series stainless steel

17-4PH and duplex stainless alloys

Grade 2 and Grade 5 (Ti-6Al-4V) titanium

Passivated or polished surface finishes

Ideal for components requiring conductivity or decorative finishes, these materials can be marked precisely without distortion or residue.

Examples include:

Red and yellow brass

Copper and beryllium copper

Nickel silver and bronze

Zinc and nickel-plated alloys

Laser marking on plastics allows for clean, contrast-rich results without melting or warping, perfect for housings and consumer or industrial parts.

Examples include:

ABS, PC, and nylon (PA)

PEEK, ASA, POM (Delrin), and PTFE

Acrylic (PMMA) and polycarbonate

Carbon fiber and fiberglass-reinforced composites

These surfaces are marked using precise energy control to remove or discolor coatings without damaging the substrate underneath.

Examples include:

Powder-coated metals and panels

Painted aluminum and steel

Chrome, nickel, or zinc plating

Cerakote, PVD, and enamel coatings

Used in high-performance or electronic applications, ceramics can be permanently marked with data, scales, or identification codes.

Examples include:

Alumina and zirconia ceramics

Ceramic-coated metals and insulators

Porcelain and technical ceramics

Oxide, carbide, and glass-ceramic layers

Laser Cutting Capabilities

Alongside marking, Nytron also provides high-accuracy laser cutting services. Our CNC-controlled systems deliver clean edges, tight tolerances, and repeatable results for sheet metal and thin components.

Capabilities:

-

Cutting thickness up to 6 mm (material-dependent)

-

Suitable for stainless steel, aluminum, and mild steel

-

Fine features, contours, and micro-holes

-

Fast turnaround for prototypes or production

-

Minimal heat distortion and excellent edge quality

Applications:

-

Precision mechanical parts

-

Gaskets and plates

-

Enclosures and brackets

-

Instrument panels and labels

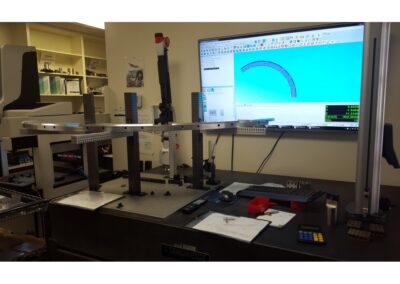

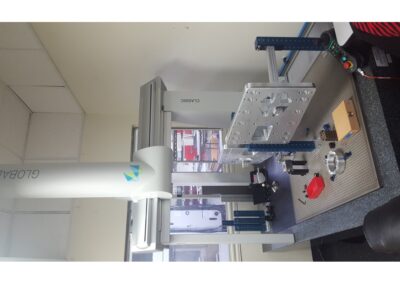

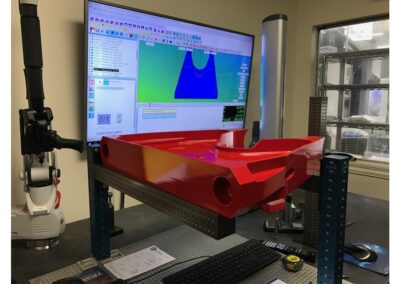

Quality You Can Trust

All marking and cutting operations are performed under strict process controls and quality assurance procedures.

Each job is verified for dimensional accuracy, contrast, and readability to ensure compliance with customer and industry standards.

Highlights:

• Documented calibration and verification process

• Readability testing for barcodes and DataMatrix codes

• Traceability documentation for every batch

• In-house inspection and visual verification

TURNKEY PROJECTS

Production Machining

Production runs from 200pcs to 100,000pcs

TURNKEY PROJECTS

Rapid Prototype Machining

Advanced Rapid Prototyping Technology